RBB Machines

RBB, a well-established manufacturer of glass-processing machines and equipment, ranks foremost in the industry. It designs and manufactures glass cutting machines: cutters for armored flat glass, drilling machines, shapers, sorters and a wide array of lifting equipment.

Lifting Units

The RBB range of lifting equipment has been designed to meet a vast range of needs and includes suction cup lifting devices that can be used both by manufacturers for workshop handling purposes and during on—site assembly and installation.

MANUAL UNITS

Mobile equipment items featuring manually controlled movement. Can be equipped with manual 360° rotation only (with 80° increments) and also a manual tilt mechanism for vertical and horizontal positioning. Suitable for glass sheet lifting, these units are easy to use and are particularly suitable for glass handling in workshops. The suction system, which features an independent electrical vacuum pump, has two safety circuits and a grip that ranges from 180 Kg to 1080 Kg.

The electrical system is supplied with the voltage rating requested by the customer and can also be fitted with a switching device that allows use with three—phase, single—phase and continuous 24V power supplies.

POWERED UNITS

Designed to handle heavy weights and meet high output requirements, these powered suction cup units feature 360° rotation and horizontal—vertical tilt. High performance machines, they are particularly suitable for large sheet assembly work on building sites and workshop handling. They feature a remote push-button control unit (up to 4 m distant), thus giving the operator excellent manoeuvrability. The suction system, which features an independent electrical vacuum pump, has two safety circuits and a grip that ranges from 540 Kg to 1440 Kg.

The electrical system is supplied with the voltage rating requested by the customer and can also be fitted with a simple switching device that allows use with three—phase, single-phase and continuous 24V power supplies without having to carry out any work on the machine.

POWERED UNITS

Designed to handle heavy weights and meet high output requirements, these powered suction cup units feature 360° rotation and horizontal—vertical tilt. High performance machines, they are particularly suitable for large sheet assembly work on building sites and workshop handling. They feature a remote push-button control unit (up to 4 m distant), thus giving the operator excellent manoeuvrability. The suction system, which features an independent electrical vacuum pump, has two safety circuits and a grip that ranges from 540 Kg to 1440 Kg.

The electrical system is supplied with the voltage rating requested by the customer and can also be fitted with a simple switching device that allows use with three—phase, single-phase and continuous 24V power supplies without having to carry out any work on the machine.

Large Sheet Units

Large, thin sheets are more difficult to manoeuvre and thus require the use of specific equipment. The RBB fixed suction cup unit can lift sheets with a maximum weight range of 540 Kg — 1620 Kg. It features a vacuum governor that adjusts vacuum according to the thickness of the glass to be lifted, automatically stabilising it so as to improve performance and enhance worker safety.

The electrical system is supplied with the voltage rating requested by the customer.

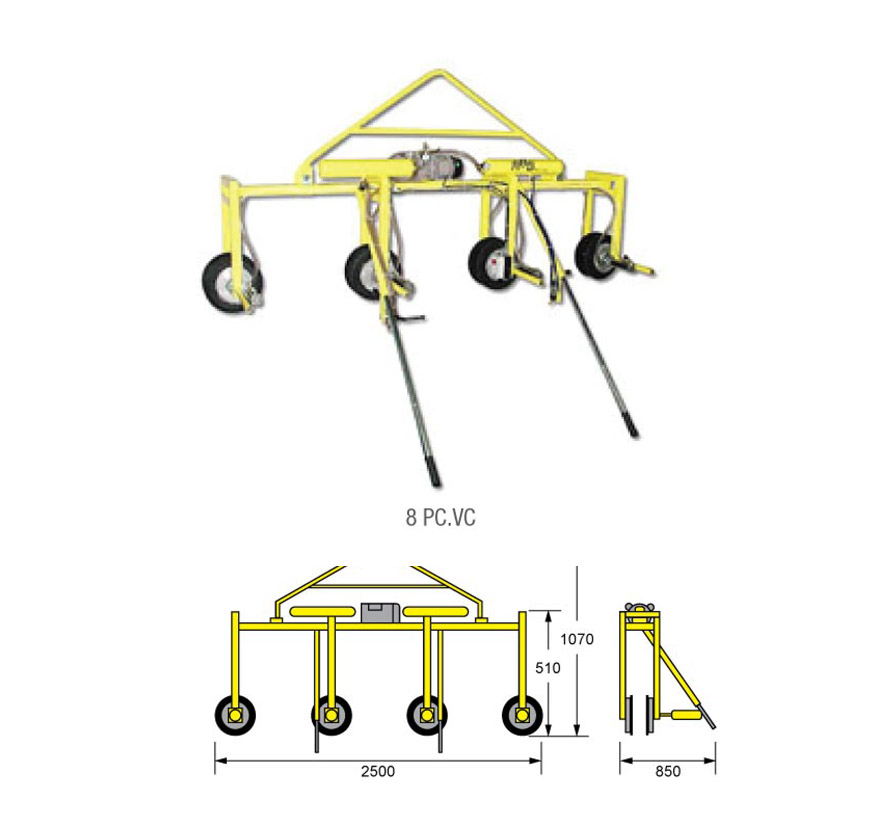

SPECIAL UNITS

This special device for double glass lifting consists of 8 opposed suction cups, four of which are moving, operated by pneumatic cylinders; it can lift sheets having a maximum weight of 750 kg and a maximum thickness of 80 mm. Fault warning optical alarm.

The electric installation can be supplied with the voltage required by the customer.

SPECIAL UNITS

This special device for double glass lifting consists of 8 opposed suction cups, four of which are moving, operated by pneumatic cylinders; it can lift sheets having a maximum weight of 750 kg and a maximum thickness of 80 mm. Fault warning optical alarm.

The electric installation can be supplied with the voltage required by the customer.

PLIERS

Mechanical equipment to be applied to a sheet lifting device. Sheet thickness 3 to 25 mm. Capacity 1000 kg max.

RACK SYSTEM

MANUAL RACK SYSTEM

Modular structure with mobile, removable racks for packs or sheets.

SEMIAUTOMATIC RACK SYSTEM

The racks are moved by a hydraulic system. The operator has a pocket-size remote control: standing in front of the rack to extract, the operator presses the foot control on the lower end of the rack itself and simultaneously presses the remote control button. The unit then opens to allow loading/unloading.

AUTOMATIC RACK SYSTEM

The racks are moved by a hydraulic system. The operator selects, from the display, the number of the rack he wishes to extract and presses the “open” key on the remote control pad. The desired rack then opens to allow loading/unloading.